Main features

- Various head types and sensing methods for diverse environments

– Thread, cylindrical, flat, L-shaped, plastic, perpendicular, stainless steel, U-shaped and area detection head types for various user requirements

– Through-beam, retroreflective and convergent reflective methods are available for diverse working conditions

-

Various Fiber Shapes & Types

-

High-Flex Cables

-

Heat-Resistant

Vacuum-Resistant

9 Head Types for Various Environments

-

-

Thread Type (Through-beam, Retroreflective)

-

-

Cylindrical Type (Through-beam, Retroreflective)

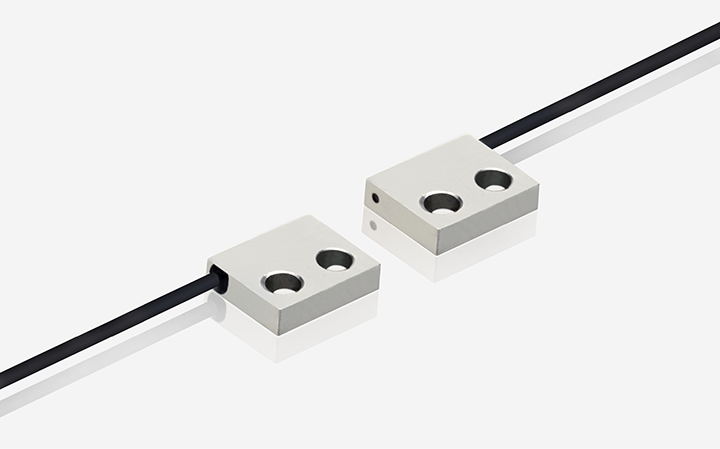

Flat Type (Through-beam, Retroreflective, Convergent reflective)

-

-

▶ Top View

-

-

-

▶ Side View

-

-

-

▶ Flat View

-

-

-

▶ L-Type Top View

-

-

▶ Top + Side View

-

-

L-Shaped Type (Through-beam, Retroreflective)

-

-

-

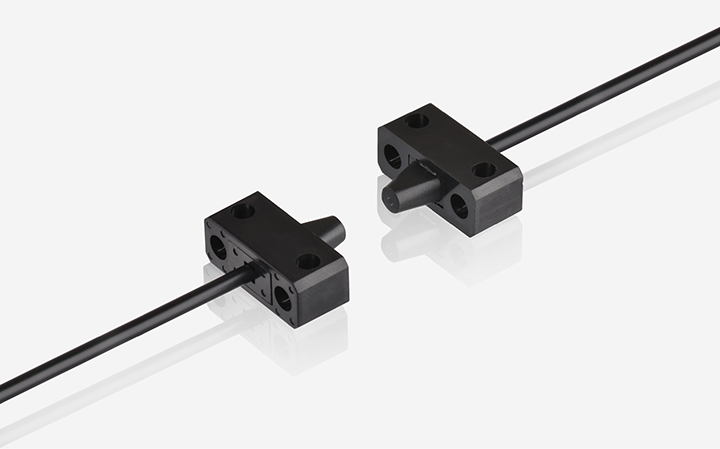

Plastic Type (Through-beam, Retroreflective)

-

-

-

Perpendicular Type (Through-beam, Retroreflective)

-

-

-

Stainless Steel Type (Through-beam, Retroreflective)

-

-

-

U-Shaped Type (Through-beam)

-

-

Area Detection Type (Through-beam, Retroreflective)

Various Cable Types Available for Diverse Environments

-

-

Standard Type Standard fiber optic cables

-

-

-

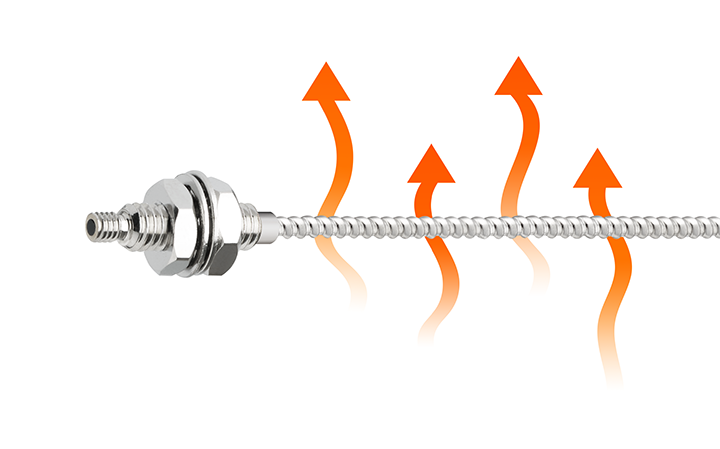

Heat-Resistant Type Withstand extreme temperature conditions from -60°C to 350°C

-

-

-

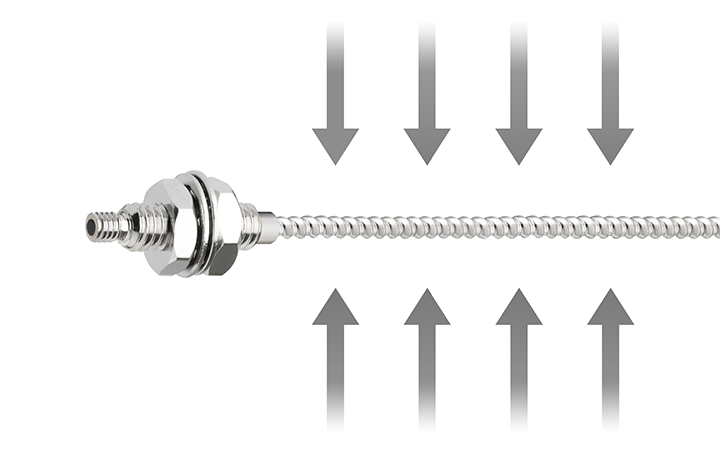

Vacuum-Resistant Type Withstand vacuum conditions from -60°C to 350°C

-

-

-

Break-Resistant Type R5, Withstand frequent bending without breaking

-

-

Flexible Type R1, Ideal for installation environments with contours. (R1>R5)

Applications

-

Wafer Baking Equipment

Fiber optic units are used to detect wafers in extremely high-temperature environments.

-

Manufacturing Process

Fiber optic units can be used to confirm presence of the trays in manufacturing lines